3 Steps to Achieve Energy Savings

Unlock Hidden Energy Savings: Your system holds the key

%

Reduction in steam production costs

Understand your current system

When was your steam system last

tested?

Uncover hidden energy losses and

identify failed traps that could be

costing you thousands

Implement simple solutions

Looking for ways to minimze your

carbon footprint?

Act on survey findings with quick

fixes to deliver measurable energy

and cost savings

Proactively monitor your system

Want to lower maintenance &

energy costs?

Stay ahead of failures and guarantee

peak performance by regularly

testing your steam traps

One failed open trap can waste up to 75.8 lbs of steam every hour.

A Good Steam Trap Delivers

- Long Life & Reliability – Durable parts cut downtime, repairs, and costs.

- Corrosion Resistance – Built to withstand harsh, acidic conditions.

- Air Venting – Clears air for efficient heat transfer and smooth startups.

- CO₂ Venting – Prevents acid buildup that can damage your system.

- Back Pressure Performance – Operates flawlessly under return‑line pressure.

- Dirt Tolerance – Handles debris without clogging or failure.

Step 1: Understand your current system

By understanding your system and spotting issues early, you prevent unplanned outages, extend equipment life, and cut energy waste while staying aligned with sustainability and compliance goals.

%

of steam traps fail every year

Step 2: Implement simple solutions

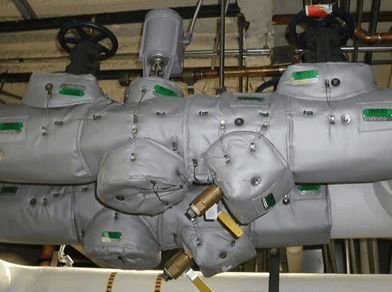

Finding inefficiencies is just the start, turn insights into impact. Implement quick, cost‑effective fixes that deliver big results. Simple steps like insulating steam pipes and auxiliary lines or recovering valuable thermal energy can dramatically cut heat loss, lower energy costs, and boost system efficiency—all with minimal effort and maximum return.

Step 3: Proactively monitor your system

Lock in your gains with proactive monitoring. After fixing inefficiencies, keep performance high by regularly testing steam traps and using easy‑to‑deploy monitoring tools. Catch issues early, prevent costly failures, and protect your investment. Consistent oversight means long‑term energy savings, extended equipment life, and a steam system that runs at peak efficiency.

A Steam Trap Survey is one of the most cost‑effective energy moves you can make.