Steam traps might be small, but they play a big role in keeping your steam system running efficiently so operations can stay focused and productive. They remove water and air, helping your system deliver heat where it’s needed.

The problem? Steam traps are often overlooked until something goes wrong. And even then, they’re not always the first thing people check. Most facilities have failed traps without realizing it, which can lead to big energy losses, especially in larger operations.

If managing steam traps feels overwhelming, you’re not alone. The good news is you don’t have to be an expert to get started. Regular steam trap surveys, when done properly, can identify issues early and provide a roadmap for improved efficiency.

By making steam trap management part of your routine, you can avoid costly problems, improve efficiency, and save thousands of dollars a year. Sometimes, what looks like a system-wide issue is just a faulty steam trap.

What is a Steam Trap and Why Does it Matter

Steam traps do more than remove condensate—they protect your system from corrosion, pressure issues, and energy loss. A good steam trap provides:

Long Life and Dependable Service: When parts wear out quickly, traps become unreliable and costly. An efficient trap saves money by minimizing trap testing, repair, cleaning, downtime, and associated losses.

Corrosion Resistance: Steam traps need to stand up to harsh conditions, including acidic or oxygen-rich water, so they don’t wear out too quickly.

Air Venting: Air can be present in steam at any time, especially on start-up. The air must be removed for efficient heat transfer and to prevent backup.

CO₂ Venting: Steam traps release carbon dioxide to prevent acid buildup that can damage your system.

Operation Against Back Pressure: Steam traps need to work properly even against the back pressure in the return system, whether that’s by design or due to system conditions.

Freedom from Dirt Problems: Dirt and scale are common in condensate. Steam traps must be designed to handle debris without clogging or malfunctioning.

A steam trap delivering anything less than these features reduces system efficiency and increases costs. When a steam trap delivers them all, your system benefits from:

-

-

- Fast heat-up of heat transfer equipment

- Maximum equipment temperature for better heat transfer

- Increased process equipment capacity

- Improved fuel economy

- Reduced labor per unit of output

- Longer equipment life with minimal maintenance

-

The Cost of Poor Steam Trap Management

Nearly every facility has some failed steam traps — often without knowing it. These failures can be costly:

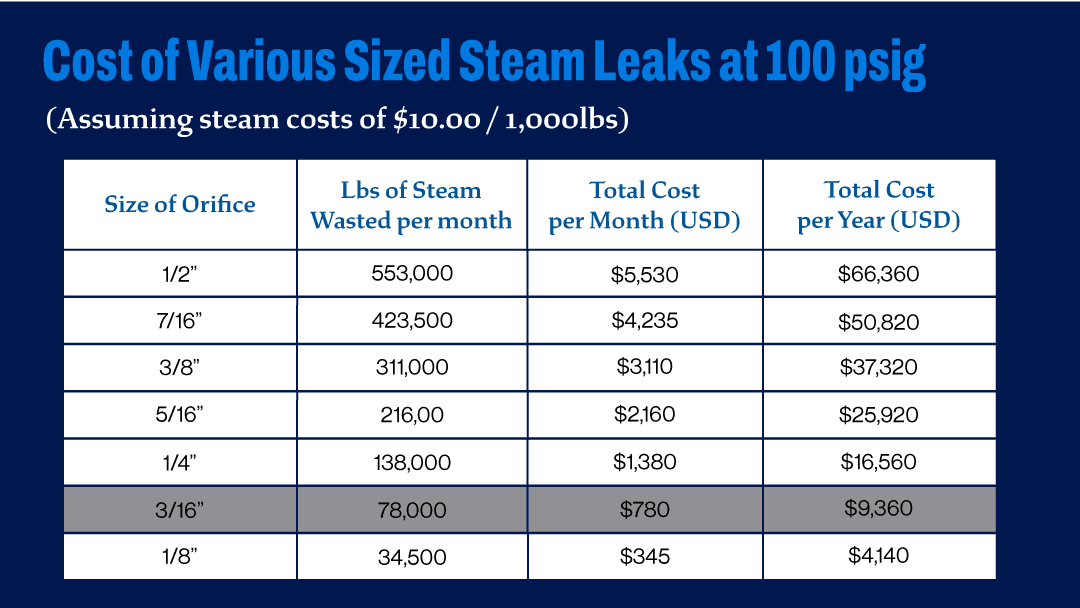

Blow-through Steam Traps: Allow live steam to escape, wasting energy — sometimes costing thousands of dollars per year per trap.

Plugged or Closed Steam Traps: Causes condensate to back up into equipment, damaging process operations and components.

Water Hammer: A safety hazard often caused by improper drainage due to failed traps.

It’s estimated that 5% to 15% of steam traps in service will fail each year. Only 20% of customers have a steam trap failure rate below 5%. A steam trap lifespan varies by type and application, but replacing failed ones generally offers a payback within 6 to 10 months.

This chart demonstrates how much energy, and money can be lost when traps aren’t properly managed.

Why Steam Trap Management is Often Overlooked

There are several ressons steam traps don’t always get the attention they deserive:

- Lack of visibility: Steam traps are small, often hidden, and don’t have obvious failure indicators.

- Budget constraints: Larger, more expensive equipment tends to be prioritizied.

- Limited in-house expertise: Teams may lack the training or tools to identify and diagnose steam trap problems.

- Misunderstood ROI: The long-term savings of steam trap maintenance aren’t always clearly understood or tracked.

Building a Smarter Steam Trap Strategy

Managing steam traps doesn’t have to be complicated. A few simple steps—like regular surveys, basic documentation, and quick replacements—can go a long way in keeping your system efficient and safe. For facilities with limited staff or complex systems, smart monitoring tools can make this even easier.

And the payoff is real. Facilities that take steam trap management seriously have seen major improvements in energy savings, reliability, and cost reduction. Even small changes can lead to big results. A quick survey can reveal hidden inefficiencies—so you can act with confidence and clarity.

Steam Trap Surveys and Education

One of the easiest ways to improve your system is through regular surveys and education. Over time, traps degrade, and without periodic testing their failures go unnoticed. A proper survey can reveal energy waste, improper piping and trapping, process bottlenecks, safety risks, and more.

Surveys are also an excellent opportunity to learn about your system. It’s important to know where your steam traps are, how they’re working, and what kind they are.

Improving your steam system’s efficiency can lead to significant energy savings, and a better system starts with more education. Looking at your steam traps can tell you a lot about how your system is running. How is your facility running? Are you running efficiently? Is your boiler working harder than it should? How much are we spending on our steam? These are all questions that can be answered when you take a deeper look at your steam traps.

Don’t wait for failure to act. Whether you’re just starting or looking to improve your current program, support is available.

Ready to optimize your system? Reach out to a Merlo Energy expert to schedule a survey or explore smart monitoring tools.

About Michael Maslov | Customer Specialist at Merlo Energy

Michael Maslov is currently a Customer Specialist with Merlo Energy. Over the past year, he has focused on conducting steam trap surveys and working with customers to improve the efficiency of their steam systems. These surveys have been foundational in his understanding of steam system design and operation, giving him hands-on experience with a wide range of equipment and facility types. Through this work, he has helped identify energy-saving opportunities and supported customers in optimizing their steam and condensate systems. Michael is based in Michigan and is continuing to expand his expertise in industrial and institutional energy management.

Webinar - Fundamentals of Steam Systems

Dive into the core of steam technology to learn about steam generation, steam distribution, and key principles and applications.

Webinar - Secrets of Efficient Steam Generation

Learn about efficient steam generation, boilers, their operations, and best practices to maintain a steam system.